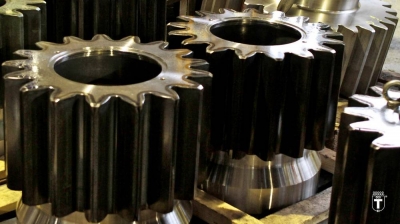

GEARS, PINIONS, CROWNS

We perform induction hardening on the sides and/or bottom of the tooth of gears, pinions, eccentric crowns, helical and herringbone toothed wheels, of various types and sizes, from module 6 to module 40 up to 5 meters in diameter and 12 tons of weight, with volumes exceeding 1000 pieces per year. They are components used in various sectors such as hydraulic presses, transmission systems, off-shore platforms, reducers, etc. made in 42CrMo4, G34CrMo4, 40NiCrMo7.

Frequently, mandatory hardening profiles are required characterized by predefined hardnesses at particular depths, for which the ability to integrate hardening systems with the creation of ad hoc inductors and related cooling equipment, know-how acquired through years of experience and research in the sector. We perform magnetoscope checks, surface hardness tests and, when required, physical sections on fine-tuning samples, in order to verify the actual achievement of the hardening profile with the necessary depth and hardness.

Frequently, mandatory hardening profiles are required characterized by predefined hardnesses at particular depths, for which the ability to integrate hardening systems with the creation of ad hoc inductors and related cooling equipment, know-how acquired through years of experience and research in the sector. We perform magnetoscope checks, surface hardness tests and, when required, physical sections on fine-tuning samples, in order to verify the actual achievement of the hardening profile with the necessary depth and hardness.